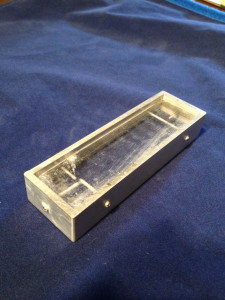

I made these jigs from 1/2 inch thick plexiglass with aluminum flat stock screwed in around the edges. The plexiglas is dead flat, and the raised edge holds the comb in place so you can concentrate on moving the combs in figure eights on a piece of sandpaper, or use the jig with the belt sander without worrying about losing control.

This tool makes it very easy to put even pressure on the combs as you flatten them.

I tried making these by gluing the frame around the plexiglas, and it worked for a little while, then the glue gave way. The version you see in the photos is put together with 2-56 screws. I had to tap the plexiglas. You could drill the whole way through and use long screws and nuts to hold the sides together, or use self tapping screws. The main thing is to make it sturdy so you don’t need to worry about it coming apart.

Then you can knock out lots of flat combs in record time!

1 Comment

Burke T.

June 3, 2013 - 7:07 amHi Richard:

I like the sanding jig idea and have tried a few diy things myself from old broken combs and 9 volt batteries to distribute even pressure. This looks like a great solution.

When you use the jig with the belt sander, do you have a way to secure the comb in the jig so that when you turn it upside down to contact the sander and flat plate under it, it stays in place and doesn’t fall out?

I think it would take destroying some combs and plates to get the hang of the belt sander, but it seems a very efficient way to go. More sawdust for my microphones!

Great job on the new site! Burke T.