This Page is devoted to ideas on tools that you can make for customizing harmonicas. Please feel free to use these ideas and if you want to make some of these tools to sell, please give me credit for the idea and let me know what you are making. If I like what you are doing, I will let people know. and that could help you sell the items.

If you are interested in making Harmonica Wax, Draw Scrapers, and other specialty tools. let me know and I can fill you in on details – or they will appear in later installments on this page.

Compact Light Box for Reed Plate Work

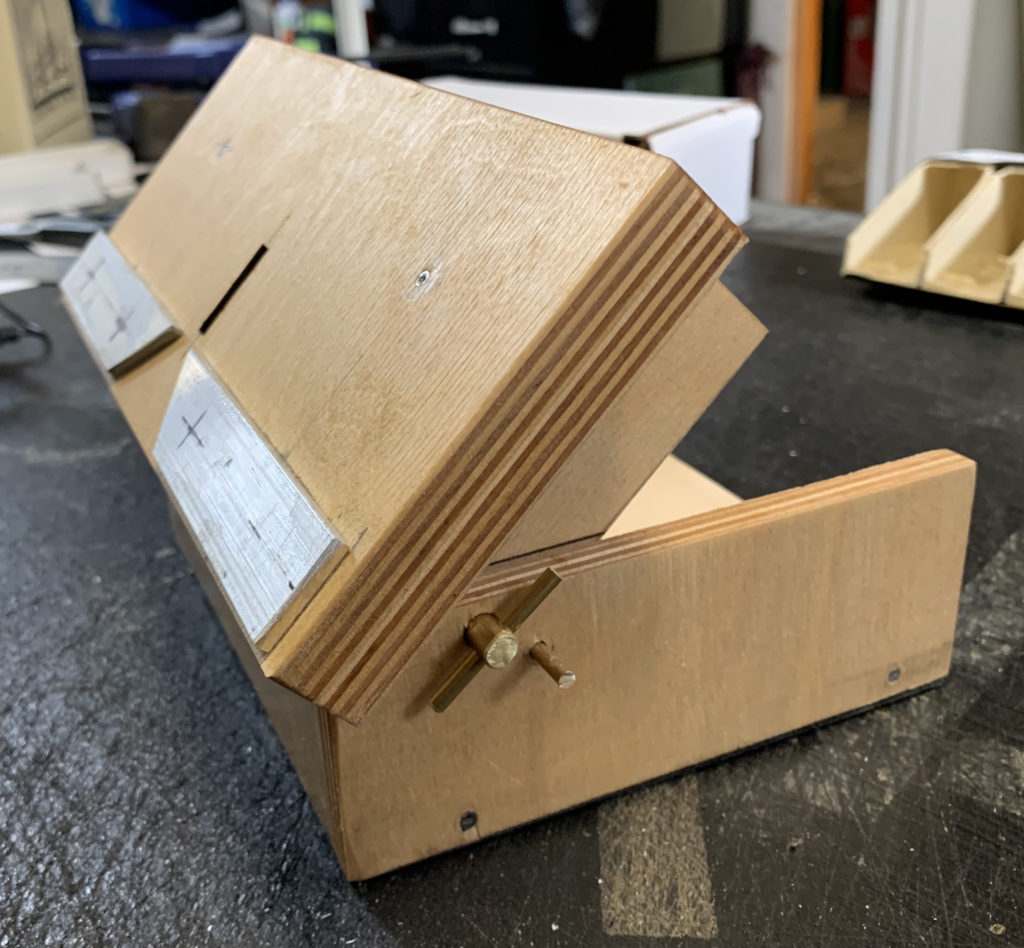

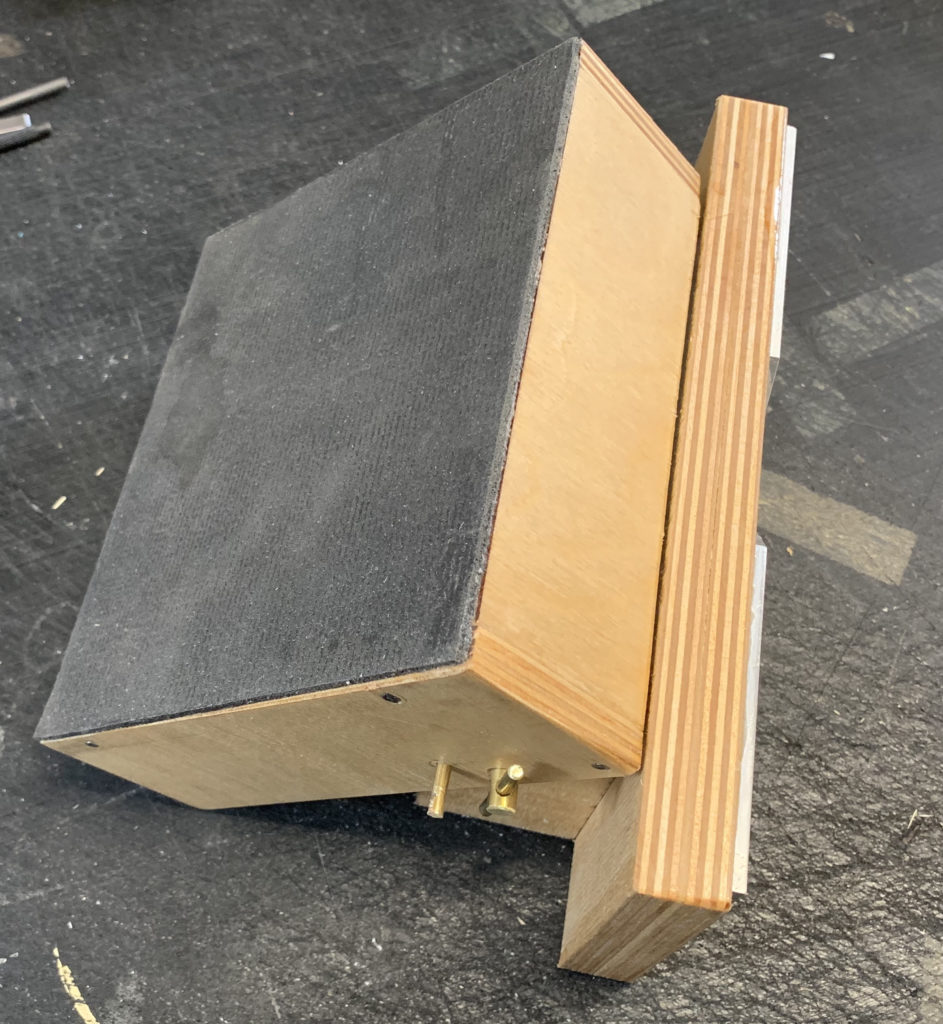

This light box was designed to collapse into a small box that would fit in my machinist tool box. The light box fixture and the clip on LED light that I use with it fit inside the top compartment of the tool box with space for the lid to close.

Here is the light box fixture assembled and ready to use – there are brass registration pins on both sides that hold the top plate at an angle that is good for viewing reeds and slots. The top plate was laser cut 1/2″ thick birch plywood with ultra thin registration slits at the top and bottom of the slot for viewing reeds. This particular model has a double thick top plate, but that is not necessary to make the box functional. I made the registration pins out of solid brass rod.

Below are additional photos of the disassembles box. Note the holes for registration pins and that the underside has tool kit liner high density foam that grips a table top and keeps the unit from slipping. The LED light fixture clips onto the workbench and you can use it to shine light through the slot for reed centering and burnishing / embossing operations. The light is fully adjustable for low or high intensity light, and the gooseneck makes it easy to relocate the light source to shine on a sheet of white paper for checking reed / slot closure with reflected light. All of the operations I am talking about are covered in detail in my Hot Rod Your Harmonica Videos. I also have additional posts on this website that go into light box use.

The Draw Scraper

I got the idea for this tool from Joe Filisko. I asked him once where he got the idea and he said “I don’t know”. So it is a bit of a mystery where this particular tool was first concieved, but I credit Joe with adapting it to the use of tuning harmonica reeds. I have had made hundreds of these scrapers made over the last 20 years or so, and the machine shop that was making them for me is no longer available.

It is made from untempered tool steel that you cut to the desired shape, temper, and then sharpen. The ideal version of this tool would be cut so that all the sides are perfectly parallel. That would make it much easier to sharpen. The closest I could get to that with my machine shop was to have the metal cut with a water jet – which leaves one side slightly angled – they then ground one side to make it a 90 degree angle to two of the sides, but there still was an angle on the fourth side that was not cost effective to deal with.

So sharpening this version of the draw scraper took extra attention to compensate for holding the small bits in place and getting the angles in shape. I used diamond cutting stones in medium and extra fine to start the process, and then did final sharpening with a white, hard Arkansas Stone. After the initial sharpening, you could dress up the edge with a couple of strokes on the hard Arkansas Stone – and I also would finish them up with a few strokes on a piece of leather with white polishing compound.

I’ve made these draw scrapers in 1/16″ thickness for the most part. I had some made in 1/8th inch width for tuning brass shruti box reeds and those draw scrapers were much easier to sharpen. I also have a couple that are 3/32″ thick and I think that is the ideal size for the width of the cutting edge – it is still very easy to get into the holes on diatonic harmonicas and is easier to sharpen than the 1/16″ thick version

Here is a pdf if a couple of drawings I sent to a machine shop that has more notes…

.

.

Recent Comments